Make the choice between a Rib and Block Slab – with Concrete Blocks vs Polystyrene Blocks

How much does Rib and Block Slabs cost in South Africa? (updated 2024)

February 11, 2022Concrete Blocks vs Polystyrene Blocks.

The conventional rib and block slab always combines a concrete rib and a concrete block. Over the last few years many Engineers (Royal Concrete’s Engineers included) introduced the idea of replacing the concrete block with a lightweight polystyrene block.

To understand why, first we need to understand the purpose of the “Block “in the rib and block slab. The Block is only a void filler, meaning it is there to save concrete, that the main purpose, and It has no structural integrity in the slab, so it can be replaced with better “blocks” that are more efficient.

So why did the Engineers want to replace the concrete block with a polystyrene block?

What are the benefits of polystyrene block vs concrete block in a rib and block slab?

- Weight: The first point is that the concrete block weighs around 22kg each and in turn 145kg per m2. This adds a lot of weight on top of a house/structures walls and foundations. For example, a rib and block slab of a 200m2 house, these concrete blocks add approximately 30 000kg (30 tons) of weight onto the structure. Not that the structure cannot handle the stress (South African engineers designed this way effectively for many decades), But by substituting the concrete block with a lighter weight “Polystyrene Block” we can remove 30 tons from the structure, and at the same time add in the benefits on insulation, faster installation, lower costs etc.! Imagine a loaded horse and trailer truck being parked on top of your house, this is the weight that the concrete block ads !

- Sound and Heat Insulation. Polystyrene Blocks bring the added benefit of assisting in insulation the home/room from cold, heat and sound. But… to efficiently insulate a structure the walls and floor of the structure needs to be insulated as well, this is an important point. So , yes, Polystyrene Blocks assist with insulating the slab roof or floor.

- Faster Installation : lightweight and longer blocks, means these polystyrene blocks are quickly installed by 1 or 2 builders.

- Lower Material Costs: This can vary from company to company, but Royal Concrete Slabs polystyrene price is lower than the concrete block price

- Lower Transport Costs: This is an important cost to reduce for the client, especially clients in looking to buy rib and block slab in provinces such as North West, Mpumalanga, Free State and Limpopo

- By removing 145Kg per m2, this polystyrene slab adds strength, meaning the slab actually take a heavier load before it is under strain. And at the same time reduces stress on the walls and foundations. This is by far the best benefit in my opinion

- Going Green. Polystyrene is eco friendly and brings benefits to the environment. It is also being widely specified by architects/engineers for use in foundation, floors and walls for insulation properties.

So all in all the Polystyrene Block has a lot of benefits stacking up in its favour,

Lets discuss the drawbacks below:

- Plastering the underside of the slab (called soffit). Plaster does not stick well to polystyrene, although there are chemicals that can make this work, the plastered surface might still be cumbersome as the years pass by. For this reason, and to avoid maintenance issues, we recommend that Rib and Block slab with polystyrene blocks, should make use of a 9mm SABS ceiling board… which can add to the cost.. But>> these days most homes use drop ceiling and use ceiling boards underneath the slab anyway for ease of electrical wiring etc.

- Mindset. Most “older generation”builders/contractors have mostly worked with the concrete block and are reluctant to try the polystyrene block, for this reason the newer generation have been the main clients for this product and is growing rapidly month to month. Some clients do not understand that the block is just a void filler and think that the polystyrene is “weak as a floor” which is untrue and the complete opposite, it provides extra strength to the slab by removing weight off the slab and structure!

Other skeptical questions clients or builders might have are :

- What happens if there is a fire? The Polystyrene Blocks are manufacture using fire retardant material, meaning in the event of a fire the polystyrene melts, the strength of the slab is on the ribs, and along with the 9mm SABS ceiling board specified, all of which are in line of 1 hour fire rating designed by engineers.

- Is the polystyrene is weak, it cannot hold a suspended floor? No, this is not true, the Polystyrene Block is a better solution, It has high density, and is part of the slab, not the entire slab is polystyrene, the concrete ready mix and concrete ribs provide the strength of the slab

Conclusion : Why are Polystyrene Blocks used in rib and block slabs?

Our engineers have decades of experience and have thoroughly tested the Polystyrene Block with Universities and concluded that Royal Concrete should have this 21st century product in our product range. It brings way too many benefits to the industry, building structures, clients and the environment. Not only is it popular in rib and block slabs, it also is being widely used in walls, surface beds and foundations to assist with insulation.

I hope this article assists you in understanding the benefits of using the Polystyrene Block.

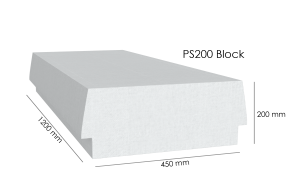

Below are illustrations for the 2 the types of rib and block slabs